First Phase Success in Biscuit Packaging

First Phase Success in Biscuit Packaging Line with Full Automation

Industry/Product Lines: Food packaging, Snacks packaging

Client Requirements:

A major international company in the biscuit industry came to Jacob White with their plans to bring operations up to date with the installation of a full production line. The first phase of installation needed a fresh approach to speed up runs of trayed biscuits to consumer cartons.

They had the following priorities:

- Packaging line with speed and size variation capability

- Easy change over process

- Fully automated solution

- User-friendly control system with minimum training required

- Good after sales and service

Our Solution

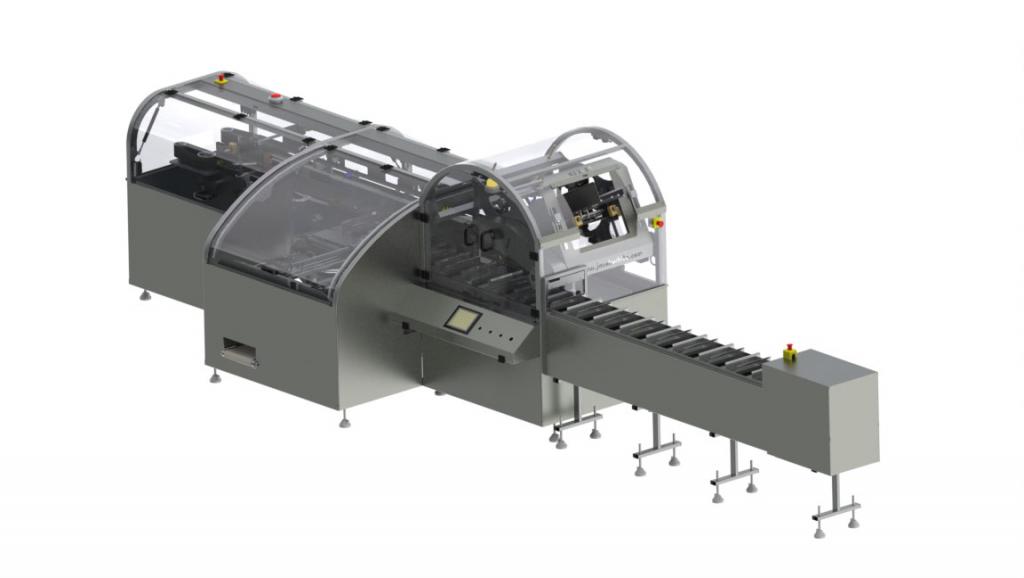

Jacob White attended site to gain a full view of the company’s current working processes and procedures. Following close consultation and review of the client’s exact requirements, we were able to recommend a fully automated solution in the NS-X 5 automatic cartoner.

These packaging machines offer a comfortable run speed of more than 200 cartons per minute, delivering the increased production speeds the client was looking for. Full automation ensures that human intervention is minimised, thus ticking the hygiene standards boxes for the biscuit industry.

The End Result

The End Result

The customer was happy to engage Jacob White to install the first phase of the new production line. The NS X-5 offered them complete automation, with integrated carton erector, automated product placement and carton sealer in a single machine. With the additional benefit of a reject unit, the NS X-5 automatically selects and discards any carton with no product outside the machine’s guard line.

This biscuit packaging solution operates using a simplified user interface with touch screen and full electronics. Both training and heavy reliance on manual resources is minimised. The speed variation and product size interchangeability offer greater flexibility and allows fast changeover with no parts required, minimising downtime and maximising productivity.

From the Customer

“The NS X-5 was the ideal packaging machine to kick start our production line modernisation project. We’ve been delighted with the first phase implementation and are impressed with the way in which Jacob White handles each stage.

The variable speed and size allow us to easily handle the changing needs of our customers and the biscuit industry. We’ve been able to operate short production runs efficiently due to the fast and easy changeovers, which typically take no more than a few minutes.

It is reassuring for us to have completed this first phase of the modernisation of our packaging production line. We’re now running cartons at more than 200 per minute, which shows us that we’re doing the right thing!”